{{item.title}}

With 3D printing, the manufacturing industry can reduce the complexity of the production process and increase the functionality of products. Printing in three dimensions is already widely used in rapid prototyping. But the benefits are not only technical in nature. 3D printing is a so-called 'strategic enabling technology' within the Smart Industry concept, which influences all kinds of elements of your business. Are you well and prepared on time to achieve sustainable growth with 3D printing, achieve significant cost reductions and accelerate the digital transformation of your company?

With 3D printing it is possible to produce high numbers fully customized 'one size batches' without increasing the costs per product produced. Manufacturing companies that use this approach at an early stage are creating a large, new market share. Another advantage of 3D printing is that physical production and the associated costs can be postponed. Because the product remains digital for longer, the 'time to market' can be significantly accelerated as well as respond more actively to sudden changes in market demand.

After many years of increased centralized production, 3D printing makes local production possible again. Producing closer to the customer leads to lower distribution costs among other things and makes it possible to respond quickly and flexibly to local needs. With the production of articles 'on demand', stock costs of products and components will also be able to drop significantly.

Also the impact of 3D printing on the implementation of your circular strategy should not be underestimated. Production is closely tuned to the demand and takes place close to the buyers. Transport movements are falling, as is the need for storage capacity. And the printing method, in which material is built up layer by layer, means efficient material use and hardly any waste. The overall manufacturing scrap rate can drop dozens of percentages compared to the current level. The materials that are printed, such as plastic, metal and glass, can also be reused.

"3D Printing is more than a technological innovation. It is a technology that has an impact on your entire business and production chain. In addition, it creates new markets and business models. How? We would like to think about this together with you."

Our specialists will gladly discuss with you the possibilities and implications of 3D printing for your company. We focus on the following topics:

Although 3D printing has captured imaginations everywhere and is moving toward the mainstream in making plastic components, it has yet to take off in mass production of metal parts. However, we believe this is changing rapidly. We expect metals 3D printing to disrupt many existing manufacturing processes and to become a fundamental part of how metal products are made in the digital age.

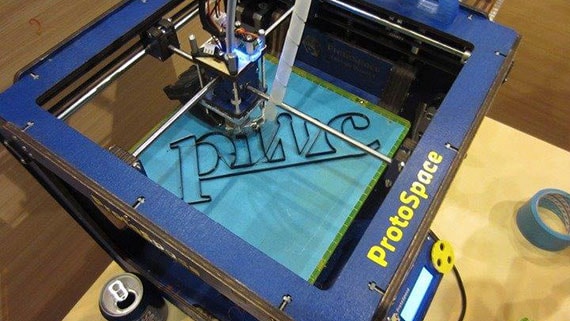

PwC is one of the strategic partners in the Smart Industry Field Lab for Multi-Material 3D Printing. This Field Lab is a strategic open innovation platform in which participants work on the next generation of 3D Printing solutions based on multi-material applications. Which business impact will this specific next generation 3D printing solutions have? PwC investigates this from a holistic approach with a focus on the underlying business case for individual companies and the sector in general. Other partners within this Field Lab are TNO, Admatec, ECN, HTSC TU / e, Nextdent, Philips Lighting, Océ and DoMicro.