The global supply chain is exposed to unprecedented levels of risk

Before the pandemic, field research by PwC and the MIT Forum for Supply Chain Innovation found that supply chain disruptions can have a lasting impact on shareholder value, taking months to recover. If the supply chain is affected suddenly, leaders can usually reassess their strategy and implement new contingencies to protect their processes in the future. But, as evidenced by the past few years, recent supply chain trends are resulting in more frequent, unexpected disruptions, each with a different mix of vulnerabilities. Leaders must have systems and plans to adapt meaningfully in real time.

This white paper explores how organisations can balance efficiency and flexibility using data insights and effective risk management while building a productive supply chain. You’ll also discover how PwC and Alteryx work with supply chain organisations worldwide to help them define and refine their risk management strategies.

Defining the right risk-mitigation strategy

An organisation’s exposure profile and risk appetite usually differ depending on the type of product or service it offers and the supply chain it needs to deliver its offering.

To define what’s right for an organisation and start building a roadmap to flexibility and resilience, there are three abilities leaders need to develop:

1. The ability to anticipate

For the parts in the supply chain characterised by less complexity and uncertainty and lower volatility in lead-time and demand forecasts, managing volatility can be as simple as positioning targeted buffers and redundancies, such as increasing stock levels ahead of an anticipated spike in sales.

2. The ability to sense, analyse, and respond

As complexity increases, absorbing volatility through simple buffering becomes more challenging. This is where organisations must establish responsiveness strategies and contingency plans, using visibility into the whole supply chain and external influences.

3. The ability to adapt and evolve

Managing volatility in complex supply chains requires a culture of continuous improvement, flexibility within the business, and strong alignment between partners throughout the chain — when something changes, everyone needs to be prepared to act quickly.

Finding the right balance is not trivial — a company’s risk management policies often prioritise anticipation, where quick response is more appropriate and vice versa. Without the right balance, companies risk inefficiently using their resources and seeing poor results. PwC’s framework features proven techniques to characterise different parts of the supply chain against volatility and uncertainty

Governing Capabilities

There are three underlaying capabilities enabling organisations to build resilience in complex dynamic environments:

- Ability to Anticipate

- Ability to Sense, Analyze & Respond

- Ability to Adapt & Evolve

Different supply chain environments require different types of capabilities, thus building the right mix is key.

A three-step process for building a more effective risk management strategy

PwC follows a three-step assessment methodology to help supply chain leaders secure business performance and continuity and protect their organisations from even the most volatile risk factors.

- Step 1: Where does your organisation stand today?

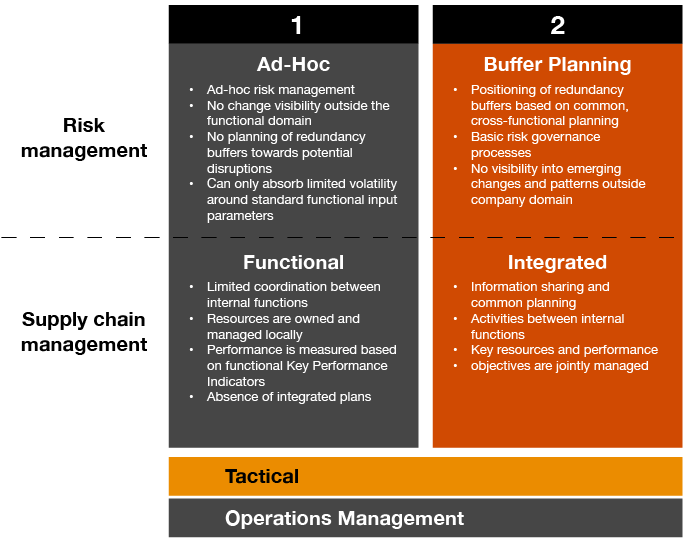

Start by considering your current maturity level. Then, compare your core supply chain risk mitigation capabilities to PwC’s classification model, assessing your ability to anticipate, respond, and adapt.

- Step 2: What should you be aiming for?

With a baseline established, you can focus on what’s ahead. The PwC methodology identifies seven enablers that can help you build the right mix of anticipation and response capabilities toward a resilient supply chain:

- Step 3: How do you achieve that goal?

Depending on the current level of maturity — and the risk profile for your supply chain — there will be capabilities that are a higher priority than others. Using advanced models and data to build digital supply chain twins provide visibility, depth, and, crucially, answers to major organisational questions and insights into your risk profile.

PwC and Alteryx offer a supply chain analytics toolkit with predictive, optimization and simulation capabilities to model and assess your supply chain’s exposure to risk and find the right mix between anticipation and response capabilities against different risk scenarios.

Download our whitepaper to find out more and reach-out to discuss what is the right risk management approach against your supply chain risks