Production comes to a standstill

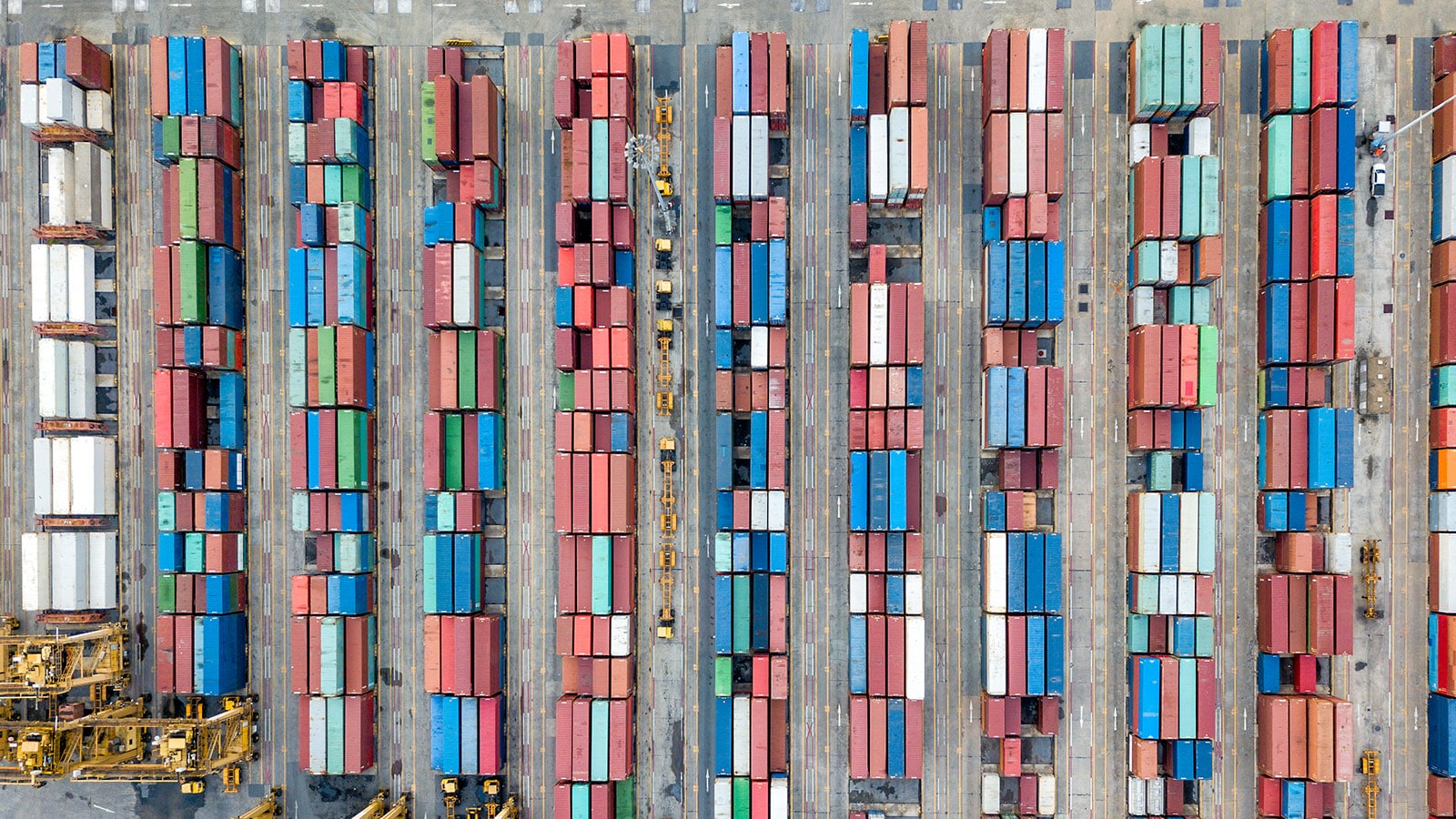

The opposite actually happened, however: during the pandemic, the manufacturer's products in fact became more popular. Demand went up, but the company could hardly deliver. When it approached its suppliers in South-East Asia, it found itself at the back of the queue with its new orders. And when a container ship also got stuck in the Suez Canal, the company's production came to a complete standstill.

The available supply within the chain

These events prompted the company's management to ask PwC to take a look at its planning process. That was also because they realised that there was now a new reality, with companies increasingly having to deal with peaks and troughs not just in demand, but above all in the available supply within the chain.

Vulnerable places identified within business process

Experts from our Operations team then looked at the company's business process. It quickly became clear that departments were working with different data and different systems. As a result, Finance didn’t know what Procurement was doing, and Sales was relying on different data altogether.

Improved structure for the supply chain

Once we had a clear picture, we worked with the company to draw up a plan for structuring the supply chain so as to suit current conditions. It became clear that a new IT system was actually needed, but implementing it would take at least eighteen months.

Data tool clarifies production sequence

Our Data Analysis team was then brought in and we came up with a faster solution. By utilising a data tool based on a number of algorithms, the company now understands which products it should produce in which order.

Components in stock and capacity

This takes into account customer demand, the components that are in stock, and capacity at the various factories. In this way, the company realised that it could still make certain high-demand products if a missing component was replaced by a variant component.

Better consultation between departments

The outcome was that the manufacturer now has a better understanding of what components are in stock, and therefore knows better what can and can't continue to be produced. But what's perhaps more important is that the new tool has helped improve consultation between the various departments.

Contact us

Partner Industrial Manufacturing & Automotive, PwC Netherlands

Tel: +31 (0)62 233 25 30